A study carried out by the Universidad Carlos III de Madrid, Texas A&M University (USA) and the Israel Institute of Technology has identified two mechanisms that produce the mechanical failure of 3D printed metals used in the aerospace and automotive industry and subjected to extreme loading conditions. This advance, which improves our understanding of how micro pores inside these metals behave, will help us design stronger materials which can be used in other fields, such as for implants in the biomedical industry.

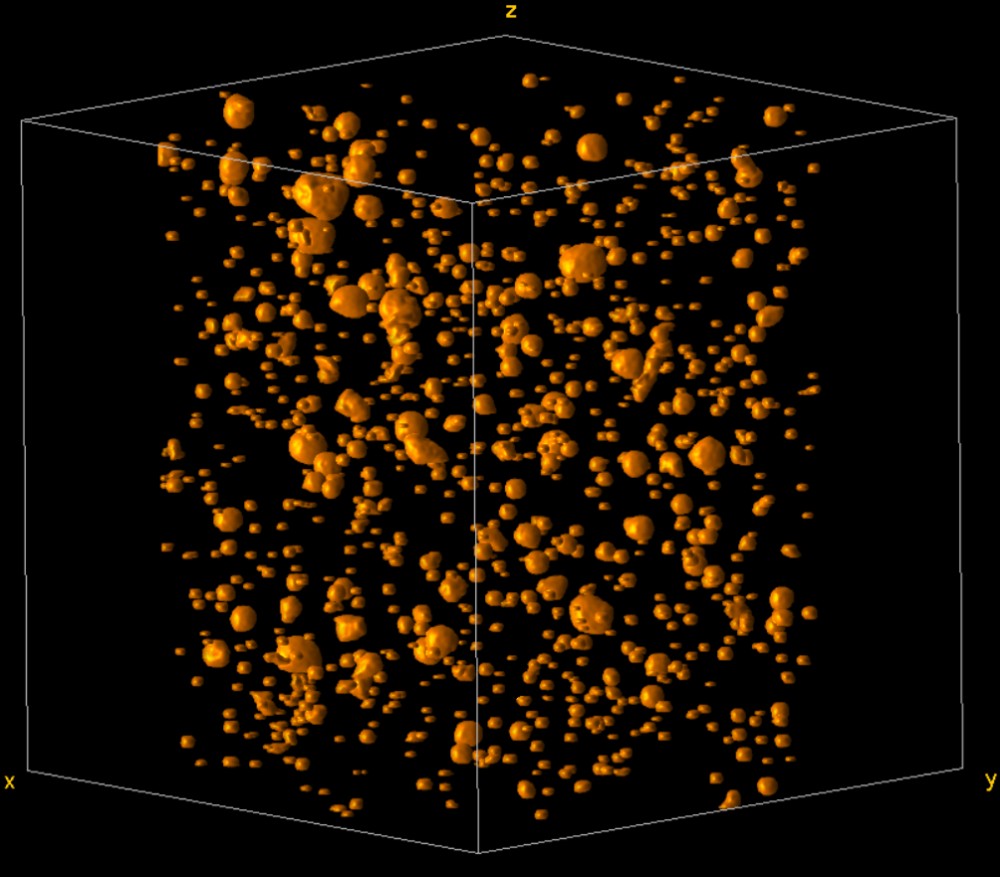

3D printed metals have been used since the 1980s to produce a wide range of parts for various industries. These materials often have tiny pores inside them (around dozens of micrometres in size), which can get bigger when a load is applied to them, due to their manufacturing process. The team of researchers has analysed what happens to these “micro voids” when applying a load to them in order to understand how these ductile metals (capable of absorbing energy) fracture.

“During this work, we have identified how the micro voids or intrinsic micro pores in the material grow, shrink and interact with each other by accelerating or delaying the fracture of this material, depending on the viscosity of the material (how quickly it deforms when a load is applied), the speed at which the load is applied to the material and the loading path (direction and other factors),” explains one of the study’s authors, Guadalupe Vadillo from the Nonlinear Solid Mechanics research team in the UC3M’s Department of Continuum Mechanics and Structural Analysis.

Advances in this field improve our understanding of how 3D printed ductile metals behave and will help us design and manufacture sturdier parts and components in a variety of industries. These materials can be used in processes where energy absorption is important, such as in the manufacture of new fuselages in the aerospace industry, different car parts in the automotive industry or for developing implants in the biomedical industry.

This research is part of the QUANTIFY project, a Marie Skłodowska-Curie Research and Innovation Staff Exchange (RISE) Action which was created to promote training and research placements among academic staff from different institutions around the world. This European research project, which is part of the Horizon 2020 programme (GA777896) is being led by the UC3M and 8 institutions (4 European and 4 American) are taking part in order to share knowledge to understand the effect of anisotropy and porosity on the breakdown of lightweight structures.

More info here.

Caption: Tomography reconstruction of an aluminium alloy manufactured using 3D printing techniques (micro voids are coloured orange).