Digital systems can only ever be as good as their underlying hardware. But what happens if electronic components are counterfeit or manipulated? Integrated circuits and electronics are key industries of the 21st century. With its flagship initiative ‘Trustworthy Electronics’ the German government aims to strengthen the international competitiveness and technological sovereignty of Europe and the European countries. Engineers at Ulm University are proud to contribute to this important political initiative with their fundamental research on electronic fingerprints. They receive funding from the German Federal Ministry of Education and Research (BMBF) of around EUR 1 million.

The researchers at the Institute of Microelectronics are involved in two collaborative projects of this initiative, with the aim to develop and implement physical fingerprints for electronic components. The idea: establishing unique identification methods for microchips and controllers to make electronic systems more secure. The two projects (VE-VIDES and VE-FIDES) are coordinated by Infineon Technologies and by Siemens respectively. They are joined by well-known companies such as VW and Bosch as well as specialist research institutions in the public and private sector. The research networks collaborate to develop tamper-proof electronic components. They also want to ensure that both the individual parts and the overall electronic systems can be tracked along the entire value chain.

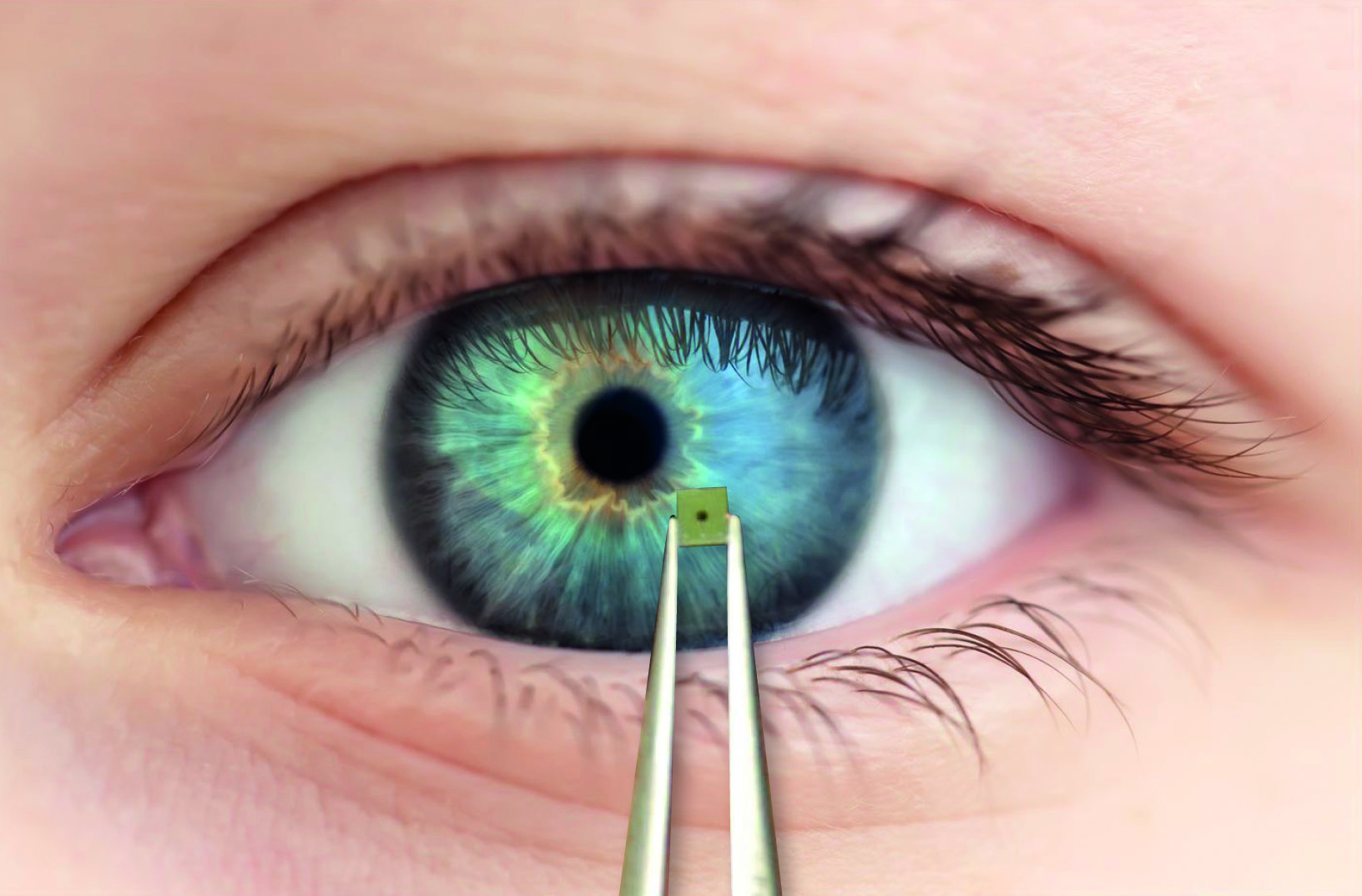

The engineers at Ulm University have set out to develop electronic circuits with counterfeit-proof physical ‘fingerprints’ for microchips, microcontrollers and printed circuit boards. This identification technology will help to determine whether a component is an original or not. Has it been modified to damage the application? ‘During the production of microelectronic components, unavoidable process fluctuations lead to tiny deviations. An initial raw fingerprint is created by capturing these random differences. Methods of signal processing and coding improve the raw fingerprint. With subsequent hardening, the final identification mark becomes robust. Such physical fingerprints make it possible to identify components throughout their entire lifecycle. They make electronic systems more reliable and establish trust,’ explains Professor Maurits Ortmanns, head of the Institute of Microelectronics at Ulm University.

Cover picture: Electronic security: physical fingerprints as unique identification can help to make microchips more secure (photo: Frank Hagemeyer, photomontage: Sabine Geller / Uni Ulm)